Email: gao@ploughlasermachine.com Tel: +86 15966330883

Home Products Laser Cleaning Machine Laser cleaning machine

Pivotal Applications Across Industries

The application spectrum of laser cleaning is vast and growing, demonstrating its value across diverse sectors.

1. Manufacturing and Metalworking: In this sector, laser systems are the best laser cleaning system for metal preparation. They are indispensable for:

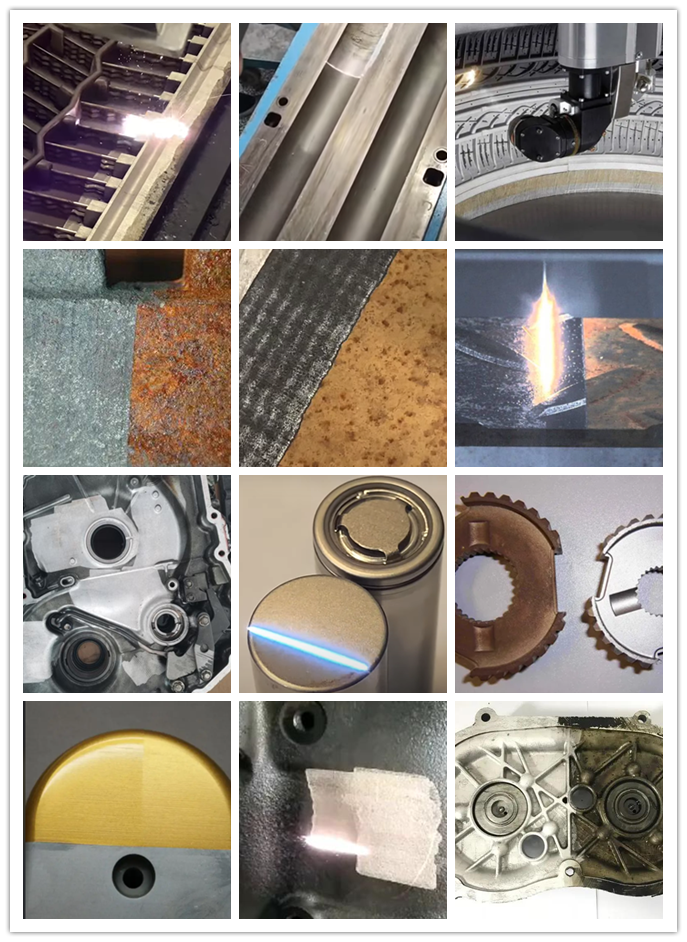

• Weld Seam Cleaning: Removing oxide layers and discoloration after welding, ensuring perfect preparation for subsequent coating or painting.

• Mold Maintenance: Efficiently stripping release agents, carbon deposits, and other residues from injection molds and die-casting tools without damaging the precision surfaces, significantly reducing downtime.

• Component Pre-treatment: Cleaning surfaces before processes like welding, bonding, or coating to enhance adhesion and product quality.

2. Automotive and Transportation: As a superior automotive laser rust remover, laser technology is used for:

• Restoring vehicle frames, chassis, and body parts.

• Carefully stripping paint from car bodies without harming the underlying metal.

• Maintaining and cleaning engine components and powertrain parts.

3. Aerospace and Precision Engineering: The high-stakes nature of laser cleaning for aerospace parts makes it a perfect match. It is used to:

• Safely remove thermal barrier coatings and oxides from turbine blades and other engine components.

• Clean sensitive avionics and aluminum alloys without inducing stress or micro-damage, which is critical for flight safety.

4. Cultural Heritage and Restoration: The gentle, non-abrasive surface cleaningcapability of lasers is a boon for conservators. It allows for the precise removal of centuries of dirt, soot, and biological growth from stone, wood, and metal artifacts without eroding the original surface.

5. General Maintenance as Laser Rust Removal Equipment: The most common application remains the efficient removal of corrosion. As effective laser rust removal equipment, it is used on infrastructure like bridges, ship hulls, and storage tanks, offering a cleaner, faster, and waste-free alternative to grit blasting.

Tangible Benefits Driving Adoption

The shift towards laser cleaning is driven by a compelling list of advantages:

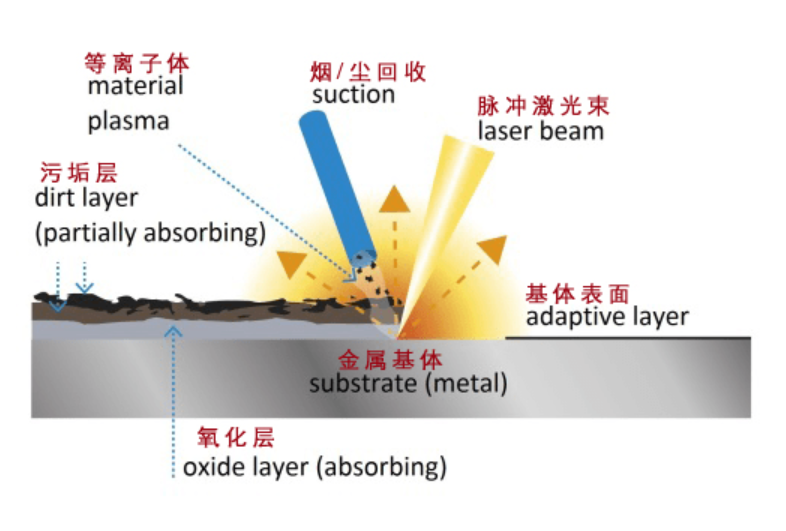

• Non-abrasive and Non-contact: Eliminates substrate damage, wear and tear on tools, and media embedding.

• Eco-Friendly and Green: The process requires no chemicals or abrasive media, generating only gaseous waste that is easily extracted with a filtration system. This addresses growing environmental and worker safety regulations.

• Precision and Control: Operators can adjust parameters to clean specific layers selectively, making it ideal for complex tasks like being a laser paint stripping machinethat removes paint without touching the primer.

• Reduced Operational Costs: While the initial laser cleaning machine price or 200W laser cleaner cost may be higher than traditional equipment, the savings in consumables, waste disposal, labor, and downtime lead to a rapid return on investment.

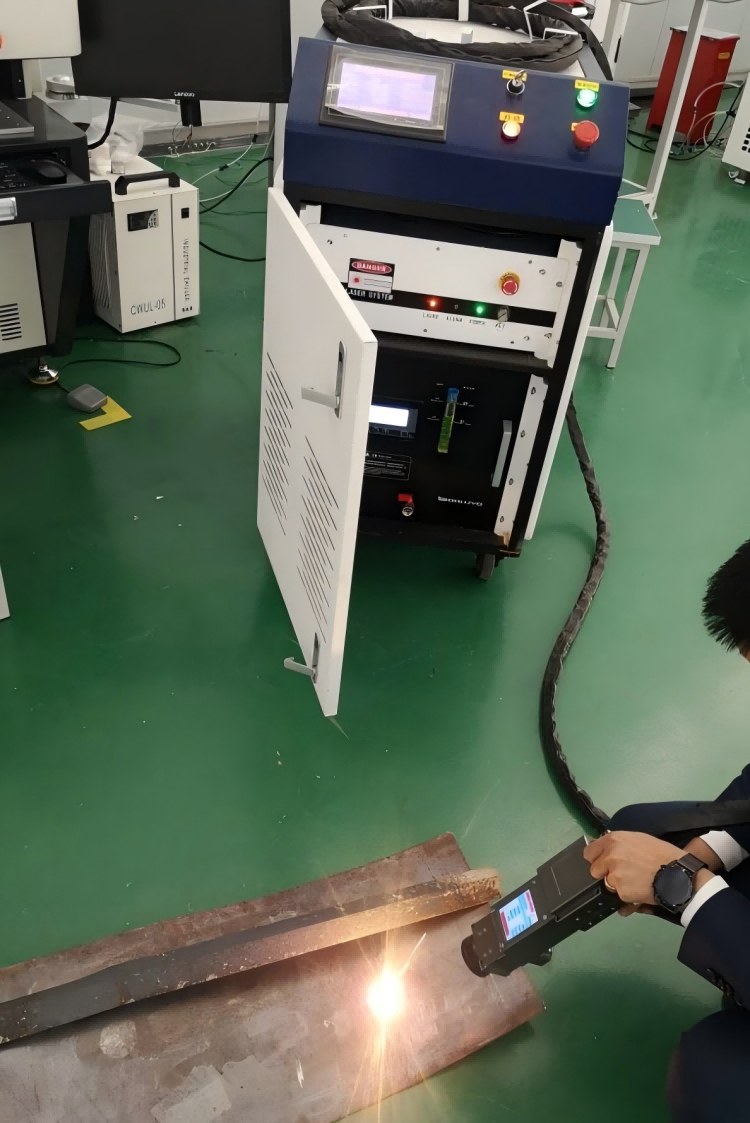

• Ease of Use and Safety: Modern systems are designed with user-friendly interfaces and integrated safety features (e.g., enclosed workstations, mandatory protective eyewear).

Name:

Mobile:+86 15966330883

Whatsapp:8615966330883

Email:gao@ploughlasermachine.com

Add:Yongqing Dianshang wuliu Park, Economic and Technological Development Zone, Liaocheng, Shandong Province